![[Translate to English:] Chickencheck bei CLK - Qualitätskontrolle von Geflügel [Translate to English:] Chickencheck bei CLK - Qualitätskontrolle von Geflügel](/fileadmin/Slider/clk_slider_chickencheck.jpg)

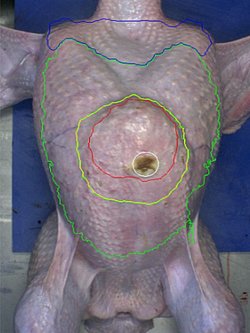

The ChickenCheck systems developed by CLK GmbH are state-of-the-art camera-based quality control systems that make a significant contribution to animal welfare, animal health, and food safety in the poultry industry. Through innovative visual analysis, these systems precisely detect and classify injuries and diseases in poultry. With their ability to assess and classify poultry into different categories, the systems set new standards in the industry. In addition to the existing systems, our experts are dedicated to developing new solutions daily to provide tailored quality control systems for individual customer requirements.

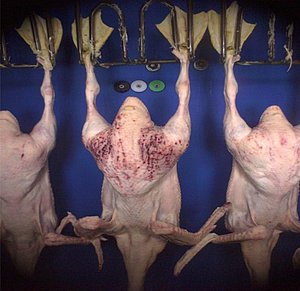

Poultry Processing Optimized - Our Wide Range of Quality Control Systems for Slaughterhouses at a Glance: