![[Translate to English:] Boxcheck von CLK - Zuverlässige Kontrolle [Translate to English:] Boxcheck von CLK - Zuverlässige Kontrolle](/fileadmin/Slider/clk_slider_boxcheck.jpg)

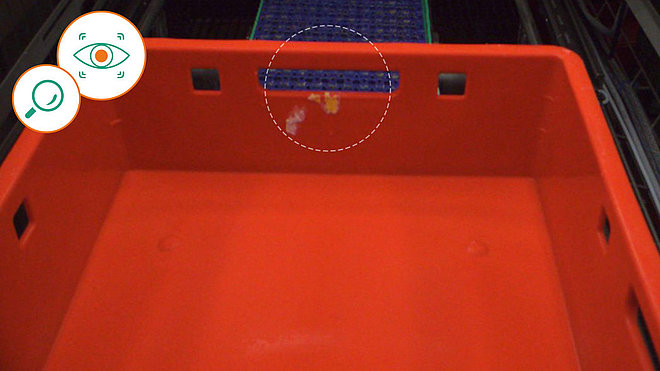

The E1 and E2 multi-purpose containers are cleaned using an industrial washing machine. Often, not all label residues are removed, or defective containers are allowed through the system. When such defective or contaminated containers continue their journey into production, they can cause a variety of disruptions.

Cracks and holes in the container's bottom can compromise its stability and sealing. Label residues, due to incompletely removed barcodes, can transmit incorrect information into the system.

The container is captured and evaluated by 6 cameras. Five cameras capture the container in incident light to detect contamination inside the container and label residues on the outer sidewalls. The damages to the container's bottom are inspected in transmitted light, slightly offset from another camera.

Defective or contaminated containers are detected by the system and can be automatically sorted out or subjected to a rewash cycle.

CLK GmbH, a specialist in industrial image processing, has developed a system for inspecting E1 and E2 multi-purpose containers to make your production more efficient and minimize costs. Leveraging our extensive experience in image processing, we identified disruptive factors in the process and developed a product that minimizes them, making your production even more efficient.

Through remote access, maintenance can be performed anytime. Our clear GUI provides you with all relevant information at a glance. Additionally, the system features automatic self-diagnosis and a configurable notification function, keeping you informed about the current status of your system.