![[Translate to English:] clk_slider_piginspector.jpg [Translate to English:] clk_slider_piginspector.jpg](/fileadmin/Slider/clk_slider_piginspector.jpg)

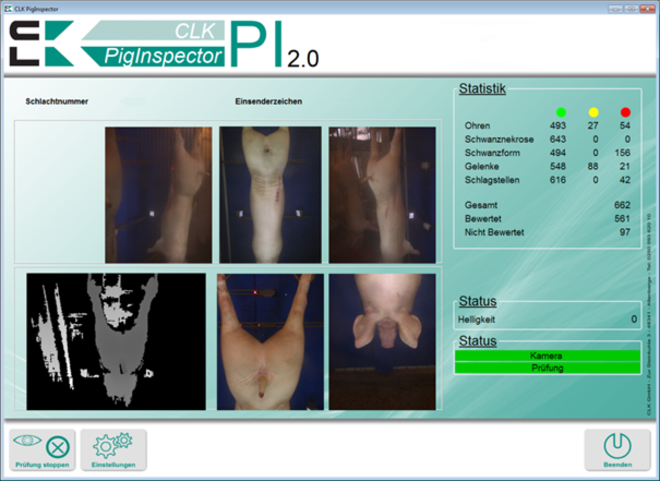

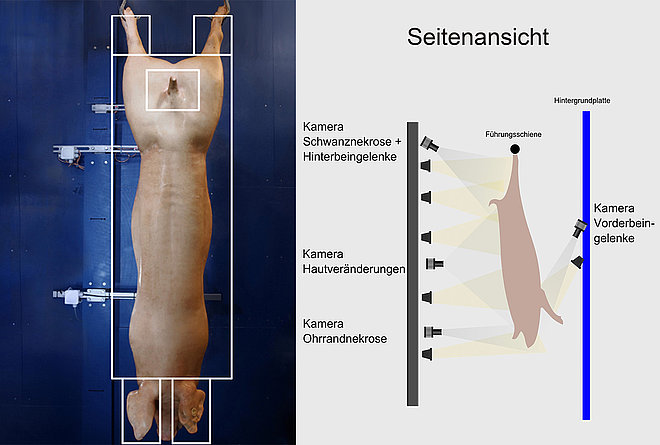

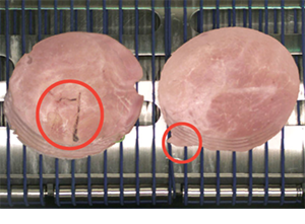

Image processing is a crucial part of pig carcass evaluation, especially in the detection of ear necrosis and tail tip necrosis. These diseases can affect meat quality and may be caused by inadequate husbandry conditions. One technology used in pig carcass evaluation is the use of 3D cameras. These cameras capture not only 2D images but also 3D data of the animal. They can be used to measure the tail length of the animal, which is essential to determine the impact of tail tip necrosis on meat quality. Another example is the use of specialized algorithms trained to automatically detect signs of ear necrosis and tail tip necrosis.

These algorithms can expedite disease detection and improve meat quality by ensuring that only animals without these diseases enter the sale. It is also possible for these algorithms to be trained to detect any skin lesions if desired.

This can help improve meat quality and reduce costs in carcass evaluation. However, it is essential to note that image processing technology is continuously evolving to achieve more accurate results. There is also limited data on the accuracy of these technologies, and the specific algorithms must be trained accordingly to achieve high precision and reliability.

It is also necessary to ensure that the image processing technology adheres to ethical standards and requirements.

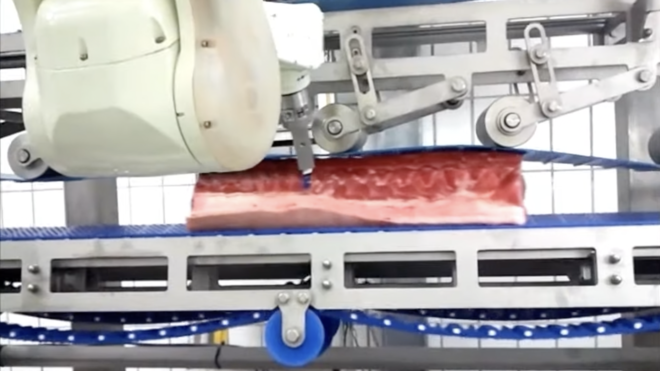

In this study, a knife is attached to a robot arm that cuts the meat against the direction of the conveyor belt's movement. The cut is individually calculated based on a camera system that relies on the optical features on the meat's surface. If the inner structure of the meat differs from the surface, the robot's cut may lead to efficiency losses in the deeper meat area.

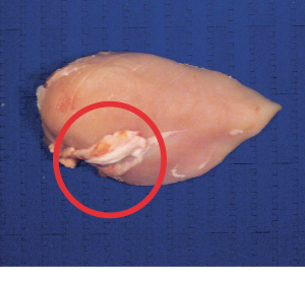

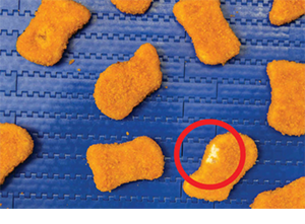

Digital image processing allows objects to be captured in 2D or 3D regardless of their position. Our systems offer simultaneous control of products regarding:

Quality assurance identifies defective products, while foreign body detection detects undesirable objects. Color detection verifies color properties, geometry analysis ensures predefined standards, and counting captures the number of products. The identification function recognizes specific products or batches, and position detection verifies precise placement or compliance with boundaries. Our systems use advanced digital image processing for reliable shape and foreign body detection in product control.

Sie haben die Qualitätskontrolle immer selbst in der Hand. Unsere Benutzungsoberfläche ist leicht zu bedienen und wird komplett auf Ihre Wünsche angepasst.

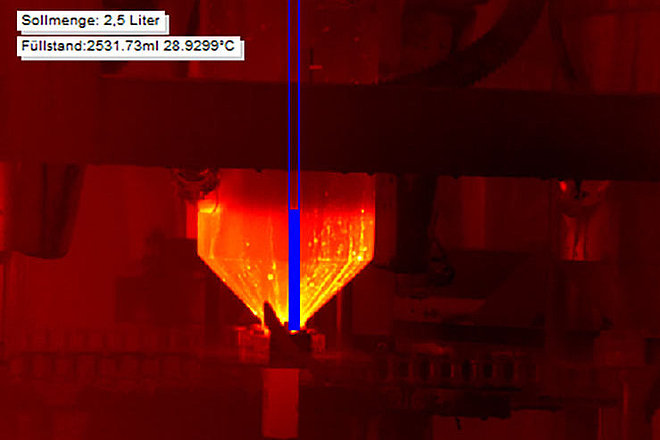

Task: Determination of the drained blood in pigs after stunning.

Solution: Determination of the fill level in the closed stainless steel container using a thermal imaging camera.