![[Translate to English:] CLK Foodtechnik [Translate to English:] CLK Foodtechnik](/fileadmin/Slider/slider_food.jpg)

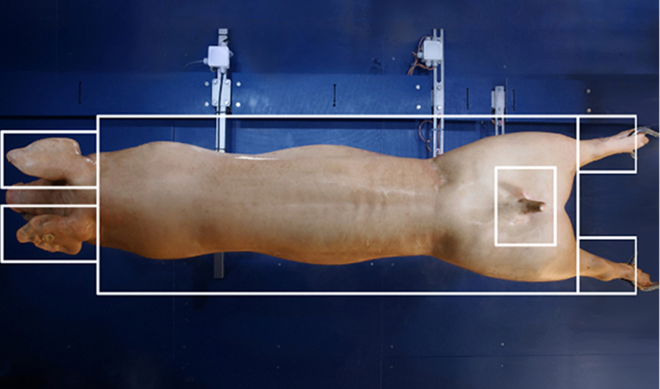

For over 25 years, our company has been a market leader in image processing and robotics for the food industry. We specialize in carcass evaluation and foreign object detection. Our innovative solutions improve product quality, increase efficiency, and ensure consumer safety. With state-of-the-art technology, we provide precise carcass evaluation and reliable foreign object detection. Our flagship products include MultiCheck, VacuCheck, ChickenCheck, PigInspector, BoxCheck, and the DokuStation.

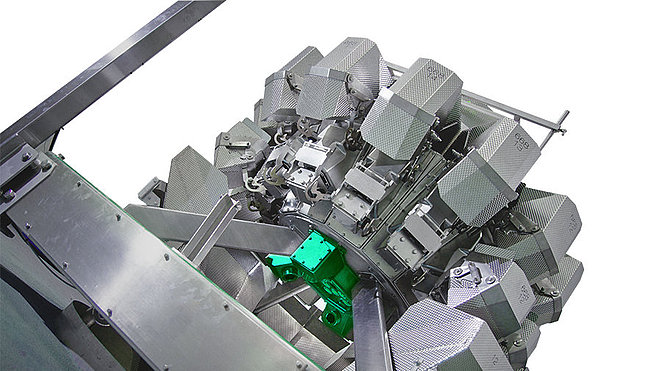

CLK GmbH, as a specialist in industrial image processing, has developed an optical system for foreign object detection. MultiCheck is installed within a multi-head scale. The functioning principle is based on color recognition. As long as the foreign object stands out in color from the product and the background, MultiCheck will detect it. The cameras cover all discharge positions to ensure that no foreign object is concealed by the product.

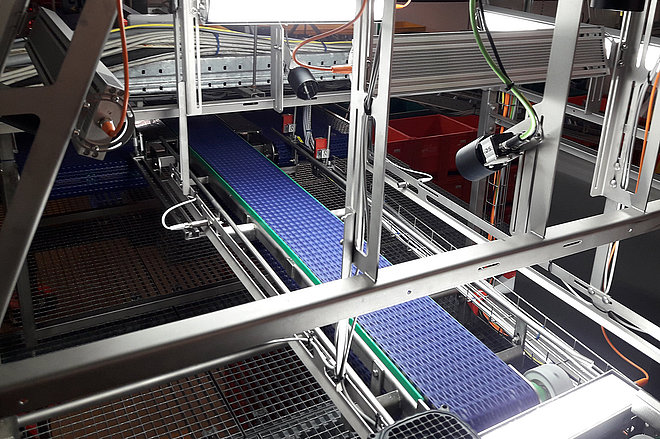

Correctly vacuum-sealed cheese packaging (pouch bags) exhibit a characteristic folding pattern at the seals. If there are leaks, this folding pattern does not occur due to air inflow. CLK VacuCheck takes advantage of this fact for objective, hygienic, and rapid optical quality control of leak-tightness. Special imaging technology captures and evaluates the relevant areas, enabling the identification of almost 100% of all leaky packaging.

read >>

We offer:

The E1 and E2 multi-purpose tubs are cleaned using an industrial washing machine. Often not all label residues are removed or defective tubs are passed through the system. If such defective or contaminated tubs find their way further into production, they can cause a variety of faults. Cracks and holes in the bottom of the tray can mean that the stability and tightness of the trays are no longer guaranteed. Label residues can transmit incorrect information into the system due to incompletely removed barcodes.

![[Translate to English:] Die übersichtliche Desktopanwendung zeigt alles was Sie wissen müssen [Translate to English:] Die übersichtliche Desktopanwendung zeigt alles was Sie wissen müssen](/fileadmin/_processed_/a/3/csm_P1150233_82ecd3f8fe.jpg)

Commissioning and Error Sources

Time pressure and product variety are two constant companions during commissioning. It is not uncommon for something to be forgotten to be loaded onto the pallet. Missing goods then lead to complaints or grievances. But was the mistake actually in your goods dispatch, or did you indeed send the pallet completely on its way? These are questions that need to be clarified in the case of a complaint.

The CLK-Rendite-System is an advanced technology that utilizes two 3D cameras to capture detailed images of broiler chickens from various perspectives. These images are then analyzed using image recognition algorithms and machine learning techniques to extract anatomical features of the animals.

E1 and E2 multipurpose containers are cleaned using an industrial washing machine. Often, not all label residues are removed, or defective containers are passed through the system. If such defective or contaminated containers continue their way into production, they can cause various issues. Cracks and holes in the container's bottom compromise its stability and leak-tightness. Label residues, due to incompletely removed barcodes, can transmit false information into the system.