![[Translate to English:] clk_slider_vacucheck.jpg [Translate to English:] clk_slider_vacucheck.jpg](/fileadmin/Slider/clk_slider_vacucheck.jpg)

To avoid product complaints, leak tests of pouch bags are essential as part of a comprehensive packaging concept for food producers. CLK has developed the VacuCheck specifically for this purpose.

Equipped with state-of-the-art image recognition and artificial intelligence, the system allows non-destructive detection of the tiniest leaks in vacuum-sealed pouch bags, all while adhering to the criteria of hygienic design. Positioned directly above the conveyor belt, the VacuCheck ensures the inspection of all products.

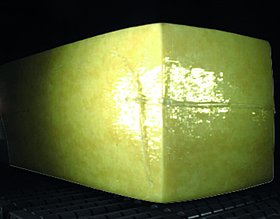

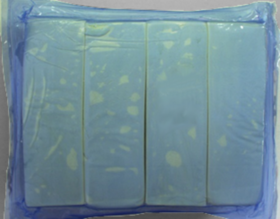

Vacuum-sealed pouch bags offer optimal protection and are used wherever long shelf life and freshness of food are crucial.

If the packaging is not 100% airtight, it can compromise the quality and safety of the products, leading to costly recalls. To reliably detect packaging defects and sort out defective bags, food manufacturers rely on precise inspection systems. Fully automated and integrated into the packaging line, the CLK VacuCheck takes on this task, inspecting up to 70 products per minute.

Thanks to advanced camera technology and AI-powered image processing, the CLK VacuCheck identifies almost 100% of all leaky packages.

The CLK VacuCheck can be installed to suit the specific requirements of the production environment.

The camera system is placed above the conveyor belt and can be easily disassembled for access to hard-to-reach areas of production. Only an encoder is mounted on the conveyor belt to synchronize the ejection process. The system can be retrofitted to existing lines with minimal effort.

![[Translate to English:] Kaese in Schleuse [Translate to English:] Kaese in Schleuse](/fileadmin/_processed_/c/6/csm_integration_138ed7017f.jpg)

When a product passes through the integrated light barriers, the cameras capture the front and back of the packaging. The images are evaluated using AI-powered processing and the results are stored in an internal database. If a defective product is detected, a signal can be sent to an ejection unit.

![[Translate to English:] Ablauf der Prüfung durch den Vacucheck [Translate to English:] Ablauf der Prüfung durch den Vacucheck](/fileadmin/_processed_/3/0/csm_vacucheck_grafik_f4bce59a6d.png)

With state-of-the-art camera technology and AI-powered image processing, the CLK VacuCheck identifies almost 100% of all leaky packages fully automated on the packaging line. A sealed pouch bag has a characteristic pattern on the surface, which is absent in an unsealed bag.

When the image recognition identifies a deviation from the defined target state, this information is forwarded in the system and the faulty packaging is automatically ejected. The advantage of the CLK VacuCheck is its inline operation above an existing conveyor belt and its suitability for high line speeds.

Vacuum-sealed products display characteristic patterns under special lighting that reveal their tightness. The software of the CLK VacuCheck can reliably analyze these patterns using artificial intelligence, making accurate statements about the condition of the packaging.

![[Translate to English:] CLK Hygienic Design [Translate to English:] CLK Hygienic Design](/fileadmin/_processed_/0/c/csm_hygiene_e434df90df.jpg)

Constructed according to the principles of hygienic design, the CLK VacuCheck features smooth, hygienic, and easily cleanable stainless-steel surfaces. The design ensures that no dirt or residues can accumulate.

As the inspection is entirely optical, there are no areas that come into contact with the product. The system also meets the requirements of the high protection class IP69, making it ideal for use in hygienically sensitive environments.

The CLK VacuCheck is designed according to the hygienic design criteria and provides complete accessibility for cleaning operations.

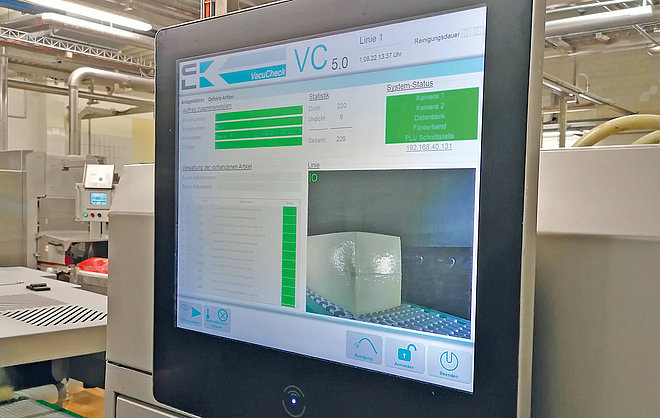

With the clear user interface, you have important production metrics at your fingertips. The system status can be continuously monitored, and any malfunctions can be immediately detected and notified via email. The user-friendly interface allows you to easily manage your products.

If a defective product is detected, a signal can be sent to an ejection unit.

The CLK VacuCheck has the potential to significantly improve the efficiency and product safety in cheese packaging. Thanks to flexible hardware and software, our systems can be easily adapted to your preferences or suggestions. We also offer an optical leak test for Euroblocks following a similar principle. It provides the same advantages as the standard version.

Additionally, it is possible to combine both tests in one system. Feel free to contact us! We will advise you and work with you to develop a turnkey solution that meets your needs.

| Merkmal | Specification |

|---|---|

| Maximum cycle rate: | 70 packages/minute |

| Operating temperature: | 0°C to +30°C |

| Relative humidity: | Max. 95% |

| Housing materials: | tainless steel, aluminum, coated acrylic glass, silicone seals |

| System size: | Standard version 1230 x 890 x 1780 mm³ |

| Illumination unit: | Individually replaceable LED modules |

| Protection class: | Camera unit: IP69, control cabinet & operator panel: IP69 |

| User input: | Touchscreen or remote connection |

| Operating system: | Windows 10 |

| Data transmission: | 10 GB network cable |

| Connection options: | OPCUA, DigitalIO (ejection signal, result output, fault messages) |

| Power supply: | 230 VAC / 50 Hz |

| Typical nominal power: | 250 W |