![[Translate to English:] CLK Multicheck [Translate to English:] CLK Multicheck](/fileadmin/Slider/multicheck_slider.jpg)

MultiCheck is an optical system based on artificial intelligence and image processing. It is specifically designed for inspecting products in multihead weighers. It can be easily integrated into new or existing systems and works fully automatically with minimal operator intervention. In 2022, CLK GmbH was awarded the Seifriz Prize and the Innovation Prize Münsterland for this patented innovation.

Users benefit from CLK GmbH's extensive experience in Altenberge with integrated automation solutions. CLK successfully utilizes a combination of classical image processing, robotics, and artificial intelligence (AI) in various areas, primarily in the food and packaging industry. Their expertise includes the development, production, and distribution of contactless quality control and positioning systems for various process tasks.

![[Translate to English:] Warum wir mehr sehen - download [Translate to English:] Warum wir mehr sehen - download](/fileadmin/images/Download-mulitcheck_CLK.jpg)

Dr. Carsten Cruse, CEO CLK GmbH

Foreign bodies continue to be a major cause of product recalls. Ensuring safe food products that are free from foreign bodies is one of the most demanding tasks in quality control. At the same time, production in the food industry is increasingly automated, and manual visual inspections have their limitations. Particularly, plastic fragments from packaging residues are difficult or nearly impossible to detect. If these foreign bodies end up in products, they can lead to not only the cost of batch traceability but also pose health risks to consumers and cause reputational damage to companies. Foreign body detection systems, usually integrated at the end of production and packaging lines, are an essential part of a HACCP concept and a requirement for successful certification according to IFS or BRC.

Even in demanding high-speed applications in multihead weighers, reliable foreign body protection is essential. This is where MultiCheck by CLK comes into play. The system combines the benefits of trained error detection with automation technology and is directly integrated into the multihead weigher.

Whether weighing and packaging confectionery, cereals, vegetables, frozen food, or fresh products such as cheese or meat, MultiCheck's state-of-the-art camera technology combined with AI-powered image processing identifies foreign bodies and sorts them out. This ensures that up to 99% fewer foreign bodies enter the supply chain, even in high-volume production lines.

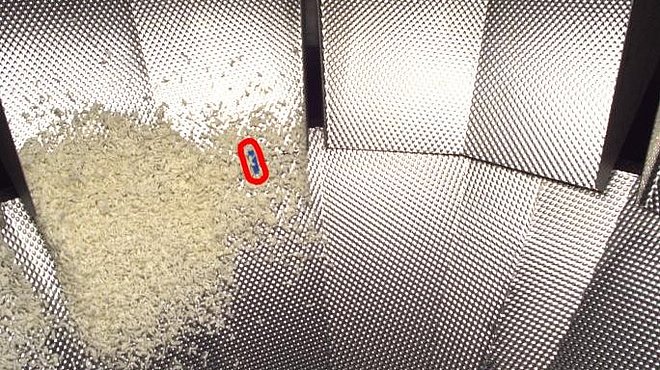

MultiCheck can detect a wide range of foreign bodies starting from a size of 2 mm x 2 mm, particularly pieces made of hard and soft plastics. The system examines defined colors (blue and red) using algorithms: As long as the foreign body stands out in color from the product and background, it is reliably detected. MultiCheck complements common foreign body systems such as X-ray and metal detectors with plastic detection to maximize production quality.

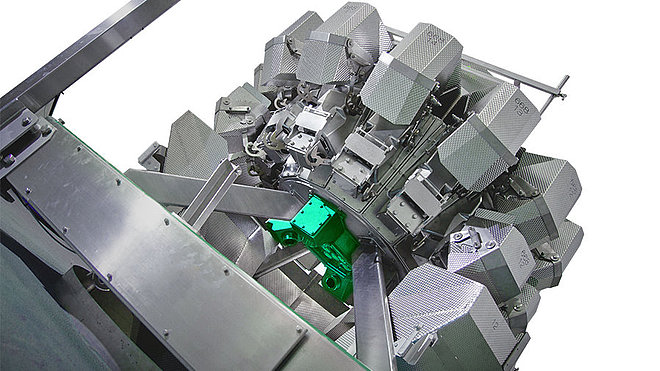

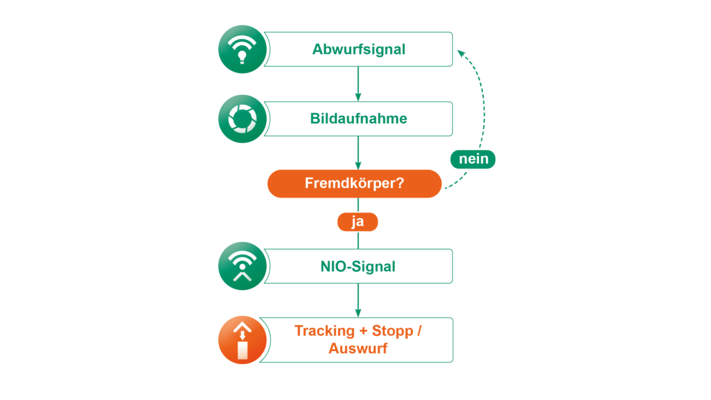

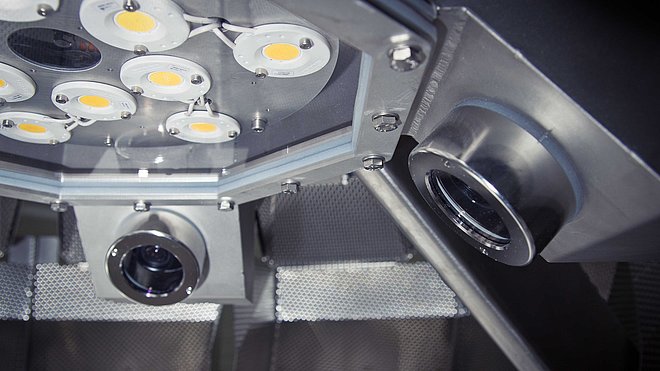

MultiCheck receives a signal from the multihead weigher when the weigh pans open, triggering the start of the image capture sequence. To ensure a full view while products are falling into the multihead weigher, four high-resolution cameras and a powerful LED lighting unit are used. A sequence of images of the product is captured for each drop. Additionally, multiple images of each drop ensure that foreign bodies hidden within the product flow are detected.

Fully automated inspection: MultiCheck handles HACCP-compliant foreign body detection, standardized according to defined evaluation criteria, independently of a human inspector.

Real-time inspection of all products: MultiCheck inspects the product stream in freefall, minimizing hidden defects.

Easy integration: MultiCheck can be integrated into most common multihead weighers with minimal operator intervention and is fully functional.

Increased safety and confidence: MultiCheck reliably detects foreign bodies based on color, regardless of density or material, including particles made of hard and soft plastics.

Early removal of foreign bodies: Foreign body inspection as the last step before packaging ensures higher safety, as no foreign bodies enter the product afterward.

Documentation of inspection processes: All detected foreign bodies are stored in an internal database and can be viewed in the software as images and statistics. Integration into customer systems is possible.

When the system detects a foreign body made of plastic or other materials based on its color, it sends a signal that can be used by the customer either for ejection or stopping the system.

The patented technology of the system relies on real-time communication with the machine control system, ensuring immediate removal of foreign bodies from the production line.

The operator terminal also displays an image of the detected foreign body, and a foreign body statistics is available in the system.

Selection of the current format via user input. Automation via OPC-UA is possible.

Display of detected foreign bodies with an acknowledgment function for findings.

Adjustable runtime statistics by camera.

Display of system status.

Error images can be stored on the system or network.

Minimal effort in case of malfunctions due to system support: Automatic validation reminders, maintenance notifications, clear error messages.

System protection through various password-protected levels for operation and administration.

The result of each optical inspection, followed by evaluation through the software, is stored in an internal database, enabling statistical long-term evaluation for objective assessment of long-term quality assurance measures. In addition, a daily statistics report on detected foreign bodies can be exported, which helps continuously improve production quality. Images of detected foreign bodies are locally stored for a defined period and can also be securely saved on a server.

MultiCheck can be seamlessly integrated with minimal effort and offers optimal efficiency for all food applications. The compact and space-saving camera system is placed directly inside the multihead weigher, providing an optimal view of the falling products without coming into contact with them. The food industry environments are characterized by a variety of hygiene requirements, including the use of acids, alkalines, and high-pressure cleaners. CLK has developed robust housings that can withstand such adverse conditions.

Camera system housing made of V4A stainless steel in IP69-like protection class.

Compact control cabinet in IP69 protection class for high-performance computers and electronics.

The system is individually adapted to the multihead weigher.

Hygienic cable routing is possible.

Scratch-resistant acrylic or makrolon windows in front of the cameras for long-lasting clarity and easy maintenance.

Operating at temperatures from -18 °C to +30 °C is possible. Intelligent flash control ensures uninterrupted operation even in direct proximity to products.

| Feature | Specification |

|---|---|

| Detectable Foreign Body Size | 2 x 2 mm ² |

| Maximum Cycle Rate | 100 drops/minute |

| Operating Temperature | -18° C bis +30° C |

| Relative Humidity | Max. 95 % |

| Housing Materials | V4A stainless steel, acrylic glass, FDA-compliant silicone seals |

| System Size | Variable, adaptable to almost any multihead weigher |

| Lighting Unit | Individually replaceable LED modules |

| Flash Frequency | > 70 Hz (non-irritating for humans) |

| Protection Class | Camera unit: IP69-like, Control cabinet & terminal: IP69 |

| User Input | Touchscreen or remote connection |

| Operating System | Windows 10 |

| Data Transmission | 10 GB fiber optics |

| Connectivity Options | OPC UA, Digital I/O (drop signal, result output, fault messages) |

| Power Supply | 230 VAC / 50 Hz |

| Typical Power Consumption | max. 500 W |

Customer satisfaction is our top priority. Our highly qualified development team is always available for our customers.

Through the use of flexible hardware and software, we can optimize our systems to meet your specific requirements.

Our expertise ranges from turnkey automation solutions with fully integrated components

to customized or series solutions, as well as detailed feasibility studies.

![[Translate to English:] Vertriebsteam [Translate to English:] Vertriebsteam](/fileadmin/_processed_/5/c/csm_csm_die-wahl-der-richtigen-strategie_5e968dc00a_23d7253c64.jpg)

Our sales team is available to answer your questions.

We would be happy to provide you with an offer for your system.

Feel free to contact

Phone: +49 2505 93620-40